Precision Die-Cutting for Double-Sided Tape: Custom Adhesive Solutions for Modern Industries

Die-cutting double-sided tape is a specialized process that transforms rolls of adhesive into custom-shaped components with precision and efficiency. By pressing a tailor-made die through the tape using advanced automated machinery, manufacturers can achieve high-speed, consistent, and cost-effective production.

This process plays a crucial role in industries such as electronics, automotive, and general manufacturing, where precise bonding, reliable assembly, and customized product solutions are essential.

The Die-Cutting Process for Double-Sided Tape

- Material Preparation

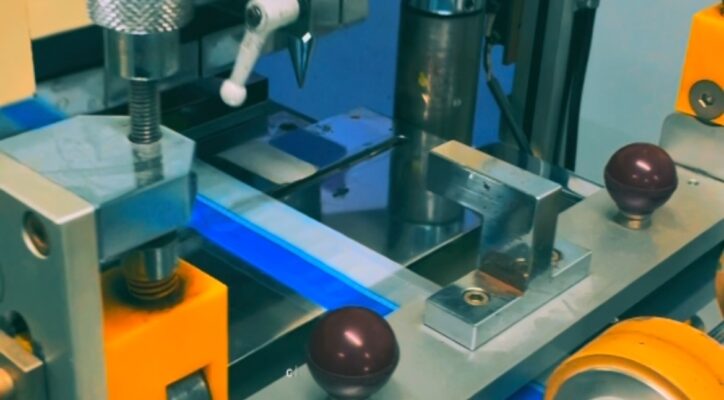

Double-sided tape, typically on a protective liner, is positioned on a supportive substrate or fed directly into specialized die-cutting machinery. - Die and Blade Setup

A custom-engineered die, designed with sharp, exact blades, is prepared according to the required shape or dimensions. - Cutting

The die is pressed onto the tape, slicing through both the adhesive layer and its liner to create the precise form needed. - Waste Removal

For certain applications, surplus material (scraps) is removed – a method known as cut with trimming – to deliver clean, ready-to-use adhesive parts. - Final Product

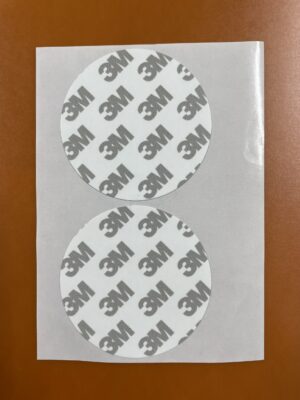

The result is a die-cut double-sided tape piece, perfectly shaped and ready for seamless integration into specialized products.

Key Advantages of Die-Cut Double-Sided Tape

- Precision & Consistency: Ensures uniform, repeatable shapes – vital for assembling complex parts in electronics and engineering.

- Efficiency: Automated high-speed machinery delivers large volumes of identical pieces, maximizing production output.

- Customization: Dies can be designed for any requirement, from simple circles to complex, intricate designs tailored to customer needs.

- Material Optimization: The process minimizes waste, making it a cost-effective solution for adhesive material usage.

- Specialized Applications: Perfect for bonding in electronics, automotive assemblies, displays, appliances, and any setting where standard tape formats fall short.

Types of Die-Cuts

- Edge-to-Edge Cut: Produces continuous strips of tape without material removal – ideal for applications needing long, uninterrupted adhesive coverage.

- Cut with Trimming: Removes surplus material around the shape, delivering clean, individual pieces (like labels or stickers).

Delivering Innovative Adhesive Solutions

Die-cutting double-sided tape is not just about cutting adhesive – it’s about delivering customized, high-performance bonding solutions that empower industries to build better, faster, and more efficiently.

With this advanced technique, manufacturers gain the flexibility to design and assemble products with unmatched precision and reliability.

—————————————————————-

Contact us to die-cutting tape your products:

Northern Industrial Technical Company Ltd.,

Address: Nghiem Thon Quarter (in Sinh Thai Urban Area), Que Vo Ward, Bac Ninh Province.

HP: +84944326255

Email: infor.nitc@gmail.com